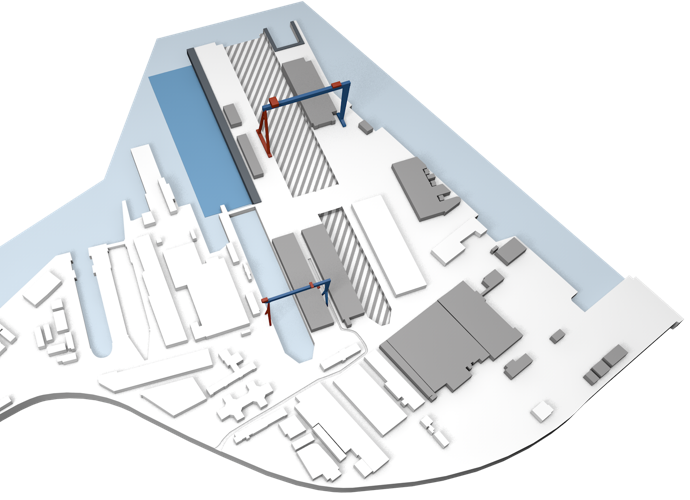

OUR WORKFLOW

Greater effectiveness and shorter delivery times - the size of our shipyard facilities and our specialised shipbuilding concept enables us to provide a modular, large-size block construction method unique to Germany that assures quality and permits a high-level of prefabrication and pre-outfitting with fittings, fixtures, equipment and systems. Find out more about our shipbuilding concept! Take a look behind the scenes at our shipyard.

Design & Engineering

The beginning of every ship building is the specification of our clients' wishes and specific requirements. For this aim our experienced engineers work together with our key partners on the development of the best technical solution. For this we involve all relevant departments. These include, besides the basic design theory draft, among others steel construction, mechanical engineering, electrics, fitting and furnishing.

The detailed design draft is executed in a complex 3D model. This creates the basis for the realisation planning and the subsequent production. During the entire process you as customer will be taken in close coordination. Our goal: a tailor-made ship meeting your requirements.

Steel cutting and fabrication of individual components

The beginning of the steel cutting process is always a very special moment for every customer as well as our employee. When our plasma cutting equipment slices the first component out of a sheet of steel, the realisation process has finally begun.

The first of up to 350,000 individual parts and components a ship can comprise are produced in Sheds 1 and 2.

Our specialists in the construction department create numerical data that control the cutting procedure. These contain the information for cutting of the openings of pipes, ducts, cables and hatches.

Shed 3 is where the fully-automated cutting of sections takes place. These are essential for providing the necessary structural rigidity. Our section robots cut and label for example flat bars, bulb flats and angle bars.

Assembly, sub-assembly & panel line production

All individual components produced are taken for further processing to Sheds 4, 5 und 6, where the are made into assemblies, sub-assemblies and substructures. These processes all follow the principles of our construction methodology. In the next step, we label and sort the various units produce in this stage of the process. This enables us to guarantee an ideal flow of materials.

Shed 6 is equipped for the production of plates from single sheets of steel. These flat elements are the basic components for the construction of a vessel’s decks and hull and may be as large as 16 m x 18 m. Minimal transportation distances from process to process guarantee an efficient workflow. A decisive factor in this is the rail transport system with several magnetic cranes connecting Sheds 1 to 6 with the external storage facility for sheet steel.

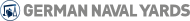

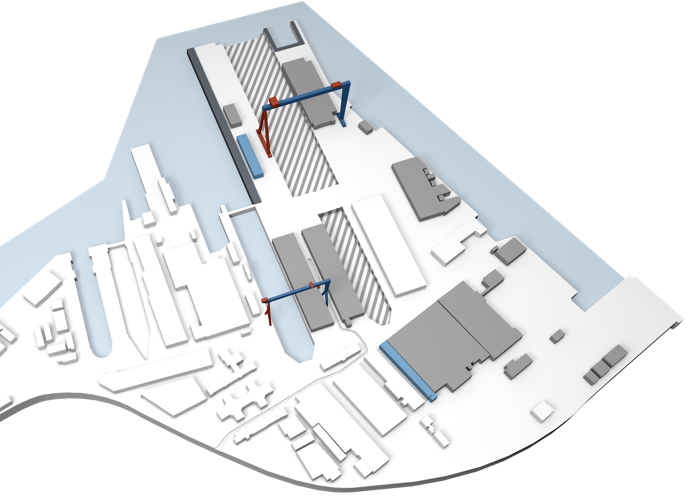

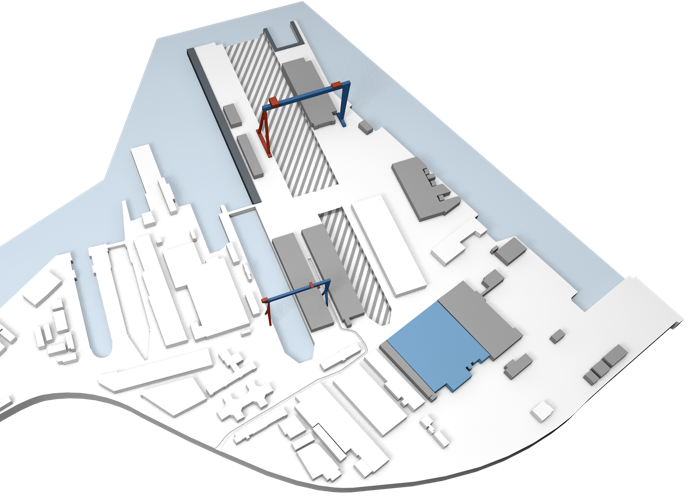

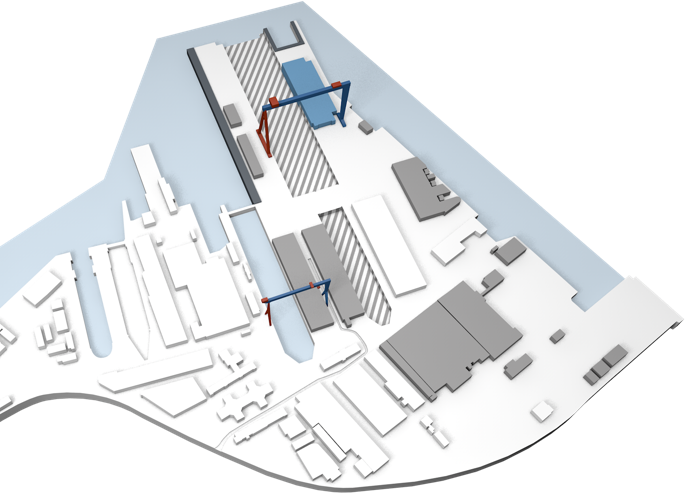

Module and large block production

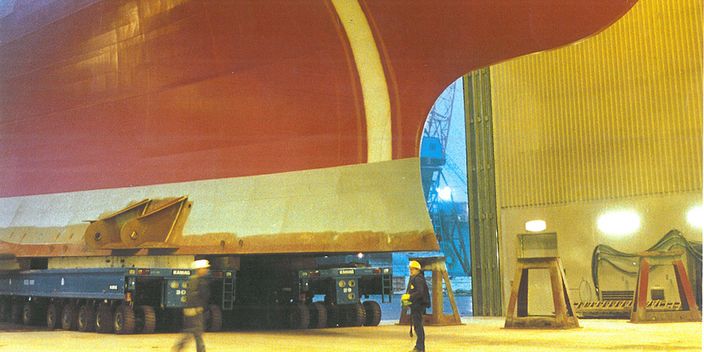

Our heavy transport vehicles and cranes move the elements from Shed 6 to the shipbuilding halls 7 and 8. The roofs of the halls can be opened by a rail system in order to allow a precise use of the 900 t portal crane.

In the shipbuilding halls, we construct sections, blocks and large-sized blocks on a working area of 5400 m² in each hall. The majority of the welding works is taking place in section and large-size block production. Here, we work inside the buildings. There we install and weld doors, ladders, pipe sleeves and all manner of other fixtures and fittings. Our large-size block construction ensures efficient and cost-effective shipbuilding processes due to the relocation of many phases of our work from the dock to the shipbuilding halls. This means we have a high level of prefabrication and pre-fitting of equipment and systems and much shorter turnaround times in the dock. This is how we achieve the highest quality standards.

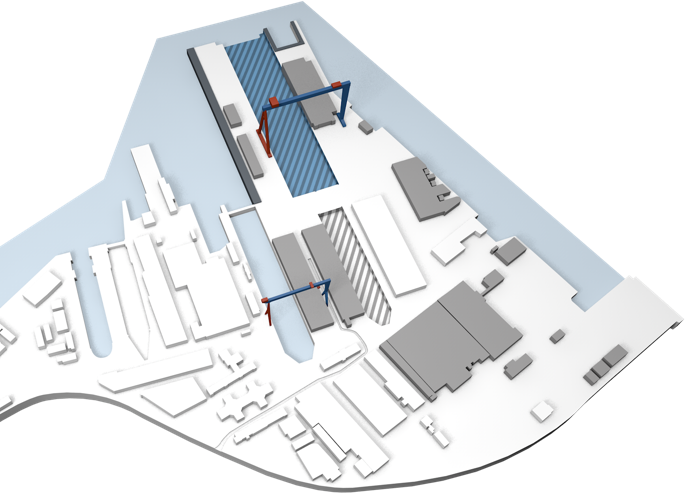

Coating & protection

We now transport our large-size blocks to the paint sheds. These are where the steel is surface-coated under strict observance of the most stringent environmental standards. The three paint sheds at our yard can be individually temperature and humidity controlled to create the best conditions for the application of state-of-the-art, high-tech coatings.

With this process, we guarantee the required protection against corrosion and limit the growth of mussels and fouling with other marine organisms. The special surface coating also contributes to a reduction of drag that results in significantly lower fuel consumption and higher speeds.

All our processes are accompanied by strict quality assurance measures. Specially trained personnel perform regular checks and analyses to ensure that our clients and customers can always rely on absolute quality.

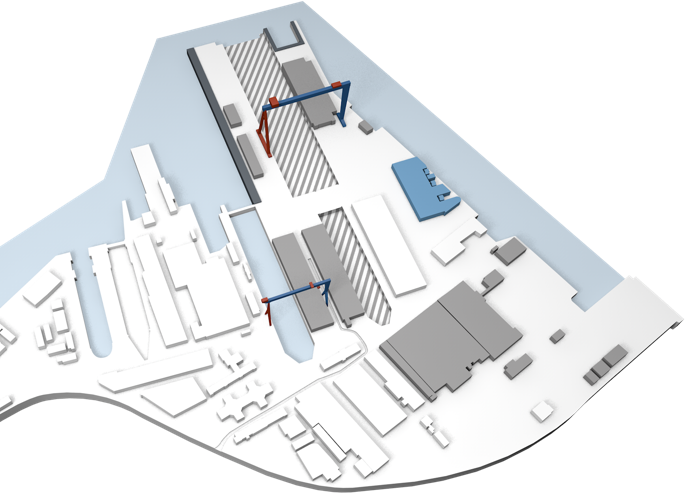

Central pre-outfitting of sections

We transport the coated sections to the portal crane on shipyard transporters especially designed for heavy loads. The crane hoists them into Shed 11, our central, temperature and humidity controlled outfitting workshop. This is where more fittings, equipment and systems are pre-installed. The distances to the neighbouring workshops and storage facilities are short. This minimises the time and effort required for tasks on board.

Central pre-outfitting comprises, for example:

- the installation of piping, cables and floors

- integration of heavy equipment such as the main engines, transmissions and switching gear

At the end of this phase, the portal crane hoists the pre-outfitted sections out of the shed through the sliding roof and lowers them to the dock.

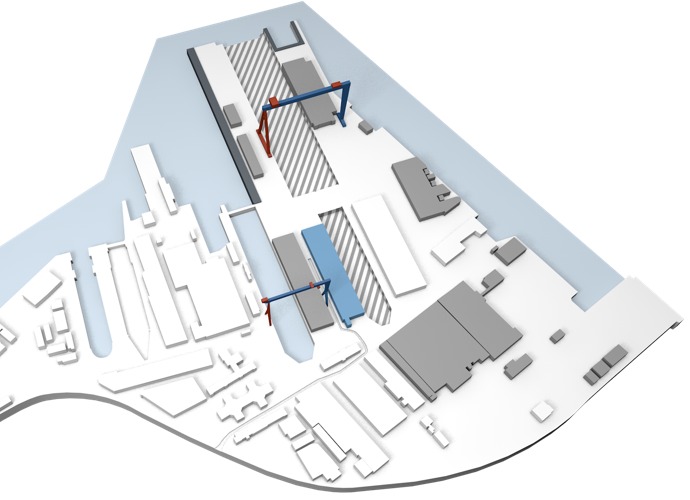

Dock assembly

The dock is where the mounting begins. Piece by piece we assemble the vessel of 5 to 7 blocks in one of our mega-docks. Thanks to our powerful portal crane this type of building is very effective. Spanning 157 m, it can reach all the relevant halls and docks of our yard.

We complete the remaining welding and coating jobs. After this, we close the hull and begin the final outfitting phase.

Testing & commissioning

Before commissioning can begin, we have to flood Dock 8a with 397 million litres of water. This takes a maximum of only four hours, thanks to an underground pipeline that pumps 99 million litres of water from the Kieler Förde into our dock per hour. The different trades carry out final testing at the pier such as harbour and sea acceptance tests. We are now ready to hand over your vessel. The new building is completed.

But we hope we will meet again. Many of the vessels we built return to our yards for maintenance or refit at some time.

And finally, we know every screw!